Services

CNC Auto Lathe

Using Computer Numerical Control (CNC), this unique machine has the ability to make intricate cuts on different types of material, specifically plastic and metal. A CNC auto lathe can be used to produce plane surfaces and screw threads or in the case of ornamental lathes, three-dimensional products that are quite complex. In any case, the work piece is held firmly in place by one or two centers, with at minimum one being moved horizontally. However, material can also be secured with clamps or collets.

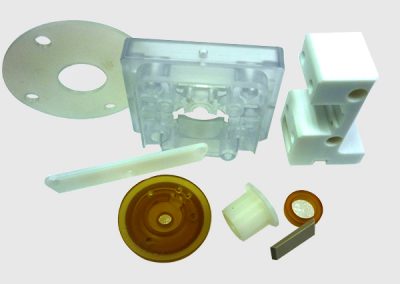

CNC Turning / Lathe

The increased complexity of products requires complex components of varying sizes and shapes. In the past, this requirement would have introduced several problems, such as increased costs as well as delays in producing the hardware. The development of computer numerical control (CNC), however, avoided that possibility. Now, it provides industries with a quick and reliable tool for machining custom parts with precision via CNC turning, which removes unnecessary material to form the desired shape.

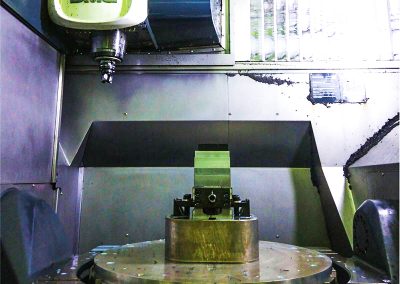

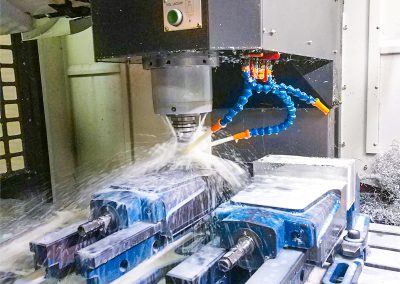

CNC Milling

CNC milling is computer numerical control (CNC). Milling utilizes a cylindrical cutting tool that can rotate in various directions. Plus, the work piece of a CNC mill can be moved across the milling tool in specific directions. The majority of CNC milling machines offer from 3 to 5 axis. CNC milling machines are traditionally programmed using a set of commands known as G-codes. G-codes represent specific CNC functions in alphanumeric format. These advanced CNC machines can produce specific shapes that are basically impossible to produce with any manual tooling techniques. In addition, most CNC mills are equipped with a special device that pumps fluid to the cutting tool during the production process.