Machine

Facility

Micro-Vu Spectra Optical Comparator

The Spectra Optical Comparators offer a large capacity stage for dimensional and profile measurements. The horizontal double-mirror design produces images that are sharp and erect.

MicroVu Vertex 210

Micro-Vu machines is for quality assurance and incoming inspection applications.

MOUNTZ TORQUE LAB – LTT Series Torque Analyzer

The torque analyzer is designed for calibrating tools, joint testing, auditing and measuring torque. Torque tools go out of calibration with use. To maintain consistent accuracy, torque tools must be checked periodically for wear or defective parts.

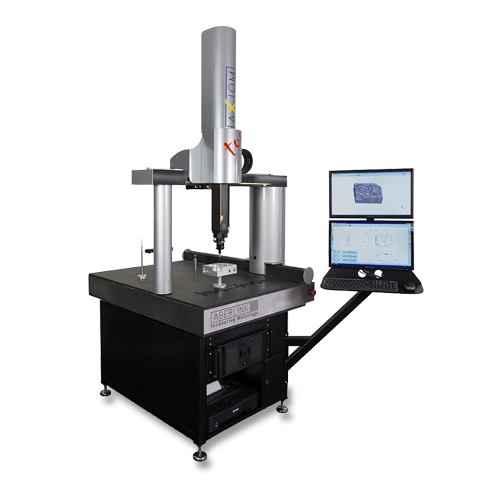

Coordinate measuring machine (CMM)

A coordinate measuring machine (CMM) is a device that measures the geometry of physical objects by sensing discrete points on the surface of the object with a probe. Various types of probes are used in CMMs, including mechanical, optical, laser, and white light. Depending on the machine, the probe position may be manually controlled by an operator or it may be computer controlled. CMMs typically specify a probe’s position in terms of its displacement from a reference position in a three-dimensional Cartesian coordinate system (i.e., with XYZ axes). In addition to moving the probe along the X, Y, and Z axes, many machines also allow the probe angle to be controlled to allow measurement of surfaces that would otherwise be unreachable.

Microscopes

Microscopes are the instruments that were developed to see those objects, which were too small to see from naked human eyes. Normally will use to check the interface of small parts.